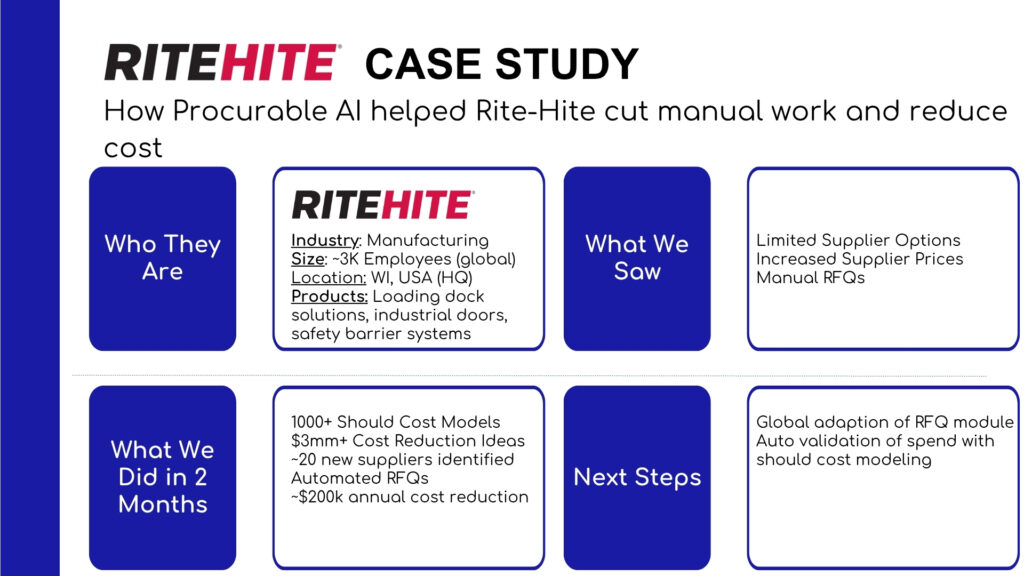

Global manufacturing leader, Rite-Hite, realizes $200K in annual awarded savings in just 2 months with Procurable AI

Rite-Hite is a global leader in the development, manufacture and sale of loading dock solutions, industrial doors and safety barrier systems. Founded in 1965 and headquartered in Milwaukee, Wisconsin, today Rite-Hite has over 3,000 employees operating across 100 global locations.

Procurable AI + Rite Hite: The Results

| Metric | Impact |

| Should-cost models created | 1 000+ |

| New suppliers discovered | ~20 |

| Identified cost-reduction potential | $3 M+ |

| Annual cost savings realized | ~$200 K |

| Time frame | 2 months |

The Challenge for Rite-Hite

Manual processes and inadequate pricing benchmarks impeded strategic sourcing.

What do a global logistics facility in Asia, a cold-storage warehouse in Europe and a manufacturing plant in North America have in common? They all rely on Rite-Hite innovations to keep their facilities running safely and efficiently. As one of the world’s leading manufacturers of loading dock safety systems, industrial doors, and in-plant barrier and flow control products, Rite-Hite solutions are installed at warehouses, distribution plants and manufacturing plants across the globe.

Like any global manufacturer, Rite-Hite must both procure tens of thousands of parts and effectively manage the supplier relationships behind them. The tariff volatility and market fluctuations of the past year led to sharply rising supplier prices, prompting Rite-Hite to reassess its supply base and exposing major gaps in its traditional procurement tools and workflows.

In their effort to find new suppliers and reduce BOM costs, Rite-Hite’s procurement team had to juggle RFQs scattered across disconnected email threads. Every piece of information had to be manually extracted and entered into spreadsheets – and whenever new details surfaced through other fragmented channels, they had to track, update, and re-enter it all over again.

Validating supplier pricing created an even more difficult hurdle. Building a single should-cost model could take weeks of analyst time, assuming these internal resources were even available. This made it nearly impossible to benchmark pricing at scale or move quickly enough to negotiate effectively.

How Procurable AI Helped

Procurable Cost Intelligence created rapid, reliable cost benchmarks at scale.

Facing a volatile macroeconomic environment and growing pressure to reduce costs, Rite-Hite turned to Procurable AI to modernize its procurement operations and gain the real-time sourcing intelligence needed to move faster and negotiate more effectively.

Procurable AI centralized Rite-Hite’s entire sourcing workflow into one platform, eliminating the need for Supply Chain Managers to search through inboxes for RFQ updates or re-enter data across multiple spreadsheets. RFQs, supplier responses, and cost breakdowns now flow automatically into Procurable AI’s single, structured workspace automatically – and without requiring time-consuming integrations to get started.

The transformation in cost analysis was just as dramatic. Procurable AI’s proprietary Cost Intelligence uses global manufacturing data, material inputs, labor rates, and production parameters to generate precise should-cost models in seconds. What once consumed weeks of (costly) analyst effort became nearly instantaneous. Within the first 60 days, Procurable AI produced more than 1,000 should-cost models, giving Rite-Hite a consistent, data-backed benchmark for every supplier quote.

Armed with this new visibility, Rite-Hite quickly identified nearly 20 new qualified suppliers and uncovered over $3 million in cost-saving opportunities. More importantly, the team could validate pricing with confidence and negotiate from a position of strength. In just eight weeks, smarter, faster decisions resulted in approximately $200,000 in annual awarded savings.

As Greg Thill, Director of Global Sourcing & Procurement, reflected:

“Procurable started to streamline our cost-savings efforts in just a few weeks. The platform’s should-cost modeling capabilities have enabled us to quickly identify items and suppliers with substantial savings opportunities. Its RFQ management tools help simplify the process of validating those opportunities through competitive quoting. Additionally, Procurable makes it easier to discover new suppliers across global regions, improving both our sourcing reach and efficiency.”

Greg Thill, Director Global Sourcing & Procurement

With Procurable AI automating repetitive steps and surfacing actionable insights, Rite-Hite’s procurement organization is shifting from reactive firefighting to strategic, high-impact sourcing.

Procurable AI + Rite-Hite: What’s Next

Scaling intelligent sourcing across categories, regions and the entire procurement lifecycle.

Encouraged by early results, Rite-Hite is now preparing to expand its use of Procurable AI across its global footprint. The next phase includes rolling out RFQ automation to additional regions, ensuring teams around the world benefit from the same speed, structure, and accuracy already achieved in the initial deployment.

Rite-Hite also plans to leverage the modelling provided by Procurable Cost Intelligence across all major spend categories — from commodity components to complex assemblies — building a unified, data-backed view of cost drivers throughout its supply base. This expansion will help the company move from validating supplier pricing to proactively identifying savings opportunities long before an RFQ begins.

Their long-term vision is a procurement organization that operates with precision and confidence, powered by continuous AI-driven insights and workflows that scale effortlessly. With Procurable AI, Rite-Hite is laying the foundation for a more transparent, resilient, and strategically aligned sourcing function built for the complexity of modern manufacturing and supply chain.